Perhaps the most fun I have had doing research! We made parachutes with the Japanese art of paper cutting known as Kirigami. Watch the 5min clip on the Nature youtube channel below or read the full paper in Nature here: https://rdcu.be/eI22w

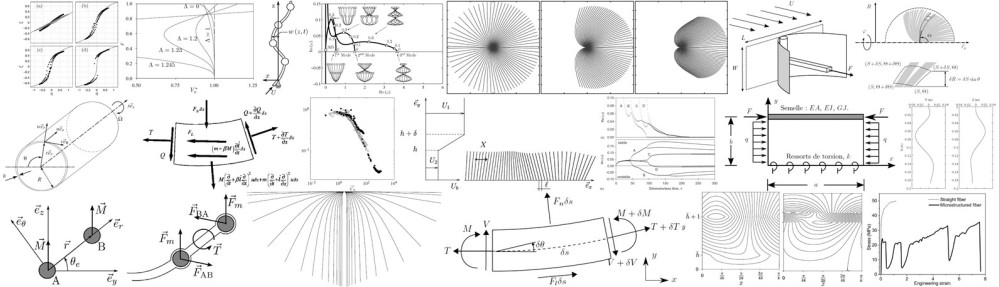

How does flutter impose a limit on drag reduction by reconfiguration

Trees and plants bend and deform under the wind, we say that they reconfigure. This elastic reconfiguration enables a drag reduction. However, a flag fluttering in the wind is a good example that flexibility can lead to flow-induced vibrations with its accompanying dynamic loads.

In her new paper, Maryam Boukor investigates the ideal flexibility that enables the best compromise between drag reduction and flutter instability. The work is the fruit of collaborative work with Augustin Choimet and my colleague Éric Laurendeau

Watch the 2min summary video below and read the full paper in Physics of Fluids.

Associate editor of the Journal of Fluids and Structures

Prof. Frédérick Gosselin proud to announce that I have accepted to serve on the editorial board of the Journal of Fluids and Structures, the best known journal in the field of fluid-structure interaction.

https://www.sciencedirect.com/journal/journal-of-fluids-and-structures/about/editorial-board

Spiderweb-inspired, transparent, impact-absorbing composite!

Shibo Zou’s new paper is out in Cell Reports Physical Science!

Dans cet article, Shibo montre comment une instabilité de mécanique des fluides peut être utilisée pour microstructurer des fibres avec une imprimante 3D, et comment, lorsqu’elles sont imprimées avec du polycarbonate, ces fibres peuvent être intégrées dans un composite transparent absorbant les chocs. Parce que les fibres se bouclent et fusionnent sur elles-mêmes lors de l’impression, elles nécessitent beaucoup d’énergie pour se briser.

Regardez un résumé vidéo d’une minute trente secondes de ce travail ci-dessous.

Lisez l’article complet ici, c’est gratuit ! (open access) https://doi.org/10.1016/j.xcrp.2020.100240

Webinar about shot peen forming (in French)

Watch the invited webinar (in French) that Prof. Frédérick Gosselin gave on shot peen forming at the Centre de recherche sur l’aluminium – REGAL.

Peen forming aircraft wing panels with Artificial Intelligence

Where should the operator shot peen a flat aluminium panel to form an aircraft wing skin?

Wassime Siguerdidjane, PhD student supervised by Farbod Khameneifar, trained a neural network with FEM to do this!

This is akin to asking “How should the panel deform to adopt the wanted shape?” This is the inverse problem! Wassime’s insight was to formulate it as a pattern recognition problem, for which Neural Networks are highly capable!

Wassime coded a maze generator and its path finding algorithm. These path solution where then turned into random, yet realistic peening patterns. These 60,000 patterns were then solved by the Finite Element Method, forming training, validation and test data sets.The key in solving these 60,000 peen forming cases by the finite element method was to treat the problem as a bilayer one. The effect of shot peening on the aluminium panel is to locally expand the surface layer, hence inducing curvature.

Once trained this way, the neural network can accurately predict the peening pattern which will lead to the wanted 3D shape for the panel. It works even for highly geometrically nonlinear cases where the plate is highly curved.

Read more in Manufacturing Letters:

doi.org/10.1016/j.mfgl…

Preprint available here:

arxiv.org/abs/2008.08049

Thanks to @FRQ_NT and Aerosphère Inc. for funding.

Vibration of a high-head Francis turbine runner

The runner of a high-head Francis hydraulic turbine is flattened and has vibration modes resembling those of a disc. When the runner rotates in water, the vibrating waves propagating in the direction of rotation and against rotation interact differently with water. There is therefore a doubling of natural frequencies. This implies that the turbine designer must work harder to identify these frequencies and ensure that no resonance phenomenon will occur on the turbine in operation.

This task is now (slightly) simplified by the new analytical model developed by Max Louyot as part of his master’s degree in partnership with Andritz Hydro Canada, published in the Journal of Fluids and Structures.

Review paper on FSI in plants

My review paper on the “Mechanics of a plant in fluid flow” is out in the Journal of Experimental Botany. This review covers the statics and dynamics of plant–fluid interactions, e.g., the static reconfiguration of a plant deforming under fluid flow, and also its dynamic swaying and flapping. It covers the mechanics at play in terrestrial plants as well as aquatic plants and seaweeds. Biological implications are highlighted and ideas for future research avenues are suggested.

Preprint is available here on researchgate and arXiv.

Our work highlighted in the Top-10 discoveries of 2018 by Québec Science magazine

Sampada Bodkhe‘s PhD work on 3D printing of piezo-electric sensors has been selected by Quebec Science magazine in its Top-10 Discoveries of the Year 2018! The breakthrough allows 3D printing at room temperature of a deformation sensor and its electrodes in one step. We demonstrate how this can be used to make smart clothes that measure breathing or movement. We also demonstrate how one can print embedded sensors on a miniature drone wing allowing to monitor in real time its vibrations.

Visit the Québec Science website to vote for her invention and make it the Top discovery of 2018 in Quebec!

3D Printing a piezoelectric sensor in one go!

Before she finished her PhD and left the Laboratory for Multiscale Mechanics at Polytechnique Montréal, Sampada Bodkhe invented a way to 3D print piezoelectric sensors in one step: she coextrudes the active sensor and the electrodes together in one go, without the need for a subsequent poling or treatment step. Just print your sensor and its ready to use!

You can read a popularized account of her work on Advanced Science News. FYI, we applied for a patent with Gestion Univalor.